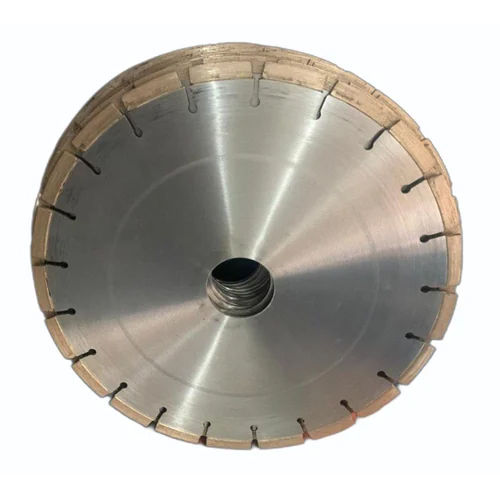

Diamond Saw Blade

1240 INR/Piece

Product Details:

- Shape Circular

- Hardness High Hardness

- Operate Method Manual and Machine Operated

- Material Stainless Steel

- Tool Type Diamond Saw Blade

- Coating Diamond Grit

- Machine Type Cutting Machine Compatible

- Click to view more

X

Diamond Saw Blade Price And Quantity

- 1240 INR/Piece

- 5 Piece

- Standard and Custom Sizes Available

- Low Vibration and Noise

- Silver with Diamond Coating

- Metal Bond

- Available in Various Sizes

- Construction, Industrial, Fabrication

- 3mm7mm (Depends on diameter)

- Circular Saw, Table Saw, Bridge Saw

- 10mm-15mm (Varies by Blade Size)

- Water-Cooled Recommended for Extended Use

Diamond Saw Blade Product Specifications

- Electroplated/Diamond Bonded

- Stone Cutting

- High Precision

- Laser Welded

- Suitable for Stone, Granite, Marble

- Diamond Saw Blade

- Optimized for Efficient Performance

- 14 inch- 54 inch Inch (in)

- Engineered for High Torque Loads

- Cutting Machine Compatible

- Dry and Wet Cutting

- Stainless Steel

- Diamond Saw Blade

- Manual and Machine Operated

- Diamond Grit

- High Durability, Corrosion Resistant, Long Life

- Diameter Based, up to 54 inch

- High Hardness

- Fast Cutting Speed

- Circular

- Segmented Cutter

- Standard and Custom Sizes Available

- Low Vibration and Noise

- Silver with Diamond Coating

- Metal Bond

- Available in Various Sizes

- Construction, Industrial, Fabrication

- 3mm7mm (Depends on diameter)

- Circular Saw, Table Saw, Bridge Saw

- 10mm-15mm (Varies by Blade Size)

- Water-Cooled Recommended for Extended Use

Diamond Saw Blade Trade Information

- 10 Days

Product Description

Details :

Application : Stone Cutting, Fabric And Blanket

Material : High Speed Steel

Number of Teeth : 32

Shape : Circular

Size (Diameter) : 10 Inch To 14 Inch

Usage : MS/GI/SS PIPE CUTTING

Packaging Type : Box

Engineered for Efficient Stone Cutting

Experience fast, precise, and smooth stone cutting with our diamond saw blades, meticulously crafted with high hardness steel and diamond-bonded segments. Each blade undergoes laser welding and electroplating, ensuring a high level of durability and strength, even under heavy-duty usage. Suitable for dry and wet cutting, these blades minimize noise and vibration while delivering superior performance.

Versatile Applications and Customization

Our blades are compatible with multiple machine typescircular saws, table saws, and bridge sawsmaking them ideal for construction sites, industrial fabrication, and specialized stonework. Choose from standard sizes or request custom arbor diameters to suit your project needs. Whether you are cutting granite, marble, or other stone materials, our blades ensure efficient, accurate results.

Long-Service Life and User Benefits

These diamond saw blades are designed for longevity and low maintenance. Their rust-resistant, stainless steel construction and high-quality diamond coating ensure consistent performance over extended periods, especially when water-cooled. They operate at high cutting speed with optimized torque, delivering clean, precise cuts and increasing productivity, while controlling operational noise and vibration.

FAQs of Diamond Saw Blade:

Q: How do I select the right diamond saw blade size for my cutting application?

A: Choosing the correct blade size depends on the cutting machine you are using and the material thickness you plan to cut. Our blades range from 14 to 54 inches in diameter and are available in various thicknesses. Refer to your saws compatibility and the type of stone you are working with or contact us for tailored recommendations.Q: What is the recommended process for cooling these diamond saw blades during use?

A: For optimal blade life and sustained cutting performance, we recommend using water coolingespecially in extended or heavy-duty cutting operations. Water minimizes overheating, reduces blade wear, and helps to control dust, ensuring smooth cuts and enhanced durability.Q: When should I use a custom arbor hole diameter for the blade?

A: A custom arbor diameter is necessary if your cutting machine has a non-standard mounting size or you require a specialized fit for a unique application. We offer both standard and custom arbor hole sizes to ensure secure and stable blade installation for all compatible equipment.Q: Where can these diamond saw blades be used?

A: These blades are suitable for a broad spectrum of environments, including construction sites, industrial fabrication workshops, stonemasonry yards, and even controlled indoor settings, provided the cutting equipment and recommended safety measures are in place.Q: What are the primary benefits of using your diamond saw blade on stone and granite?

A: Our blades are optimized for high cutting speed, precision, and durability. The high-hardness stainless steel and electroplated diamond grit ensure clean, accurate cuts even in dense materials like granite and marble. They also offer low noise, minimal vibration, and extended service life.Q: Can these blades be used for both dry and wet cutting operations?

A: Yes, our diamond saw blades are designed for both dry and wet cutting. However, for best performance and blade longevity, especially during prolonged use, wet (water-cooled) cutting is advisable.Q: What makes your diamond saw blades corrosion resistant and long-lasting?

A: The blades are manufactured from premium-grade stainless steel and feature advanced diamond bonding techniques like laser welding and electroplating. This construction resists rust and corrosion, even in moist or challenging work environments, extending the lifespan and maintaining cutting efficiency over time.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email