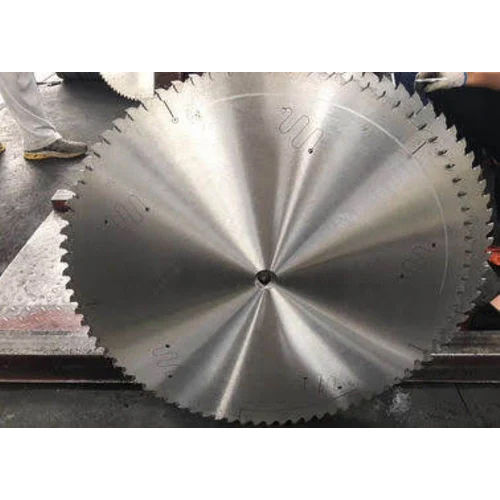

24 Inch Wood Cutting Blade

1200 INR/Piece

Product Details:

- Cutting Capacity Up to 24 inches

- Features Durable, Long lasting, Rust resistant, Clean cutting

- Cutting Force Optimized for industrial use

- Hardness High (suitable for hardwood cutting)

- Shape Circular

- Cutting Speed High

- Cutter Type Industrial Wood Cutter

- Click to view more

X

24 Inch Wood Cutting Blade Price And Quantity

- 1200 INR/Piece

- 5 Piece

- Suitable for soft and hard wood, plywood, MDF

- 24 Inch

- 3.2 mm

- 80

- Tungsten Carbide Tipped (TCT) teeth

- 30 mm

24 Inch Wood Cutting Blade Product Specifications

- 24 Inch

- Machine processed

- Uncoated

- Circular

- High

- Optimized for industrial use

- Industrial

- High (suitable for hardwood cutting)

- Wood Cutting Blade

- Automatic or Manual

- Mounted on circular saw

- High-Speed Steel (HSS)

- High Precision

- Wood Cutting Saw (circular)

- Silver

- Industrial Wood Cutter

- Wood Cutting Blade

- 24 Inch (610 mm)

- Up to 24 inches

- Suitable for heavy-duty operations

- Durable, Long lasting, Rust resistant, Clean cutting

- Suitable for soft and hard wood, plywood, MDF

- 24 Inch

- 3.2 mm

- 80

- Tungsten Carbide Tipped (TCT) teeth

- 30 mm

24 Inch Wood Cutting Blade Trade Information

- 10 Days

Product Description

Details :

Application : Stone Cutting, Fabric And Blanket

Material : High Speed Steel

Number of Teeth : 32

Shape : Circular

Size (Diameter) : 10 Inch To 14 Inch

Usage : MS/GI/SS PIPE CUTTING

Packaging Type : Box

Engineered for Precision and Durability

This 24 Inch Wood Cutting Blade showcases advanced engineering through 80 meticulously placed Tungsten Carbide Tipped teeth, delivering consistently sharp, clean, and accurate cuts. Its robust High-Speed Steel body ensures exceptional hardness and longevity, making it ideal for intensive industrial use. Designed without coating for easy maintenance, it withstands frequent use and delivers high performance even under heavy workloads.

Versatile Application Across Wood Types

Optimized for diverse applications, this blade effortlessly cuts softwood, hardwood, plywood, and MDF. Its high cutting speed and precision make it suitable for various tasks, from rough dimensioning to fine finishing, in both automatic and manual processes. Its an indispensable tool for manufacturers, workshops, and construction settings requiring reliable wood processing.

FAQs of 24 Inch Wood Cutting Blade:

Q: How do I properly install the 24 Inch Wood Cutting Blade on my circular saw?

A: Ensure your saw is compatible with a 24-inch (610 mm) diameter blade with a 30 mm bore. Power off and unplug the saw. Remove the old blade, align the new Tungsten Carbide Tipped blade, and securely tighten the flange. Double-check alignment and ensure safety gear is used during the process.Q: What types of wood can this blade efficiently cut?

A: This blade is specifically engineered to deliver clean, precise cuts on softwood, hardwood, plywood, and MDF. Its TCT teeth provide high hardness and durability, making it suitable for even dense and abrasive materials encountered in industrial settings.Q: When should I consider replacing my blade?

A: Replace the blade when you notice excessive wear on the carbide teeth, loss of cutting precision, increased resistance during cutting, or visible damage such as warping or chipping. Routine inspection ensures optimal cutting performance and safety.Q: Where is this wood cutting blade manufactured and supplied?

A: This product is manufactured and supplied in India by trusted manufacturers, service providers, and suppliers specializing in industrial cutting solutions. For local procurement, refer to suppliers serving industrial and woodworking sectors across India.Q: What is involved in the maintenance process for this blade?

A: Regularly inspect the blade for pitch buildup, resin, or debris and clean using a non-corrosive blade cleaner. Check for any damaged teeth and store the blade in a dry, rust-free environment when not in use. Proper care preserves both sharpness and longevity.Q: How can I maximize the benefit of using this blade in my woodworking operations?

A: To achieve high-precision, smooth cuts, ensure the blade is sharp, properly mounted, and used at the recommended cutting speeds. Pairing routine maintenance with correct usage significantly enhances productivity, reduces material waste, and extends blade lifespan.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email